In the highly competitive automotive industry, quality, reliability, and safety are non-negotiable standards. When it comes to producing intricate plastic components such as bumpers, dashboards, and interior trims, choosing an injection molding manufacturer with ISO certification can make a significant difference. These certifications serve as a hallmark of adherence to internationally recognized quality management systems, ensuring that every product meets stringent safety, durability, and performance standards. An ISO-certified automotive injection molding manufacturer signifies a commitment to excellence, consistent results, and continuous improvement, giving automakers confidence that their parts are produced under verified quality protocols.

The Significance of ISO Certification in Automotive Manufacturing

ISO certification is more than just a label; it embodies an organization’s dedication to process excellence and customer satisfaction. For automotive injection molding manufacturers, ISO standards such as ISO 9001 and IATF 16949 are particularly relevant, as they focus on quality management specifically tailored to the automotive sector. These standards establish comprehensive frameworks for quality control, risk management, and process optimization, which are crucial in achieving consistent production outcomes. By working with an ISO-certified manufacturer, automakers can be assured of receiving parts that meet all required performance metrics, adhere to legal and safety regulations, and maintain uniformity across large production runs. Certification acts as a reassurance that the manufacturer adheres to best practices and is committed to maintaining high standards throughout every production phase.

Ensuring Consistent Quality and Reliability

One of the core benefits of partnering with an ISO-certified automotive injection molding manufacturer is the assurance of consistent quality. Continuous process monitoring, routine audits, and systematic documentation are integral components of ISO standards. These elements help to identify potential issues early, prevent defects, and minimize variations in product quality. A certified manufacturer rigorously follows set procedures, tests parts at various stages, and maintains meticulous records to trace issues back to their source. This rigorous approach ensures that every bumper, dash panel, or interior component produced aligns precisely with specifications. Consistency in quality not only reduces rework and scrap costs but also boosts customer confidence in the final product, which is essential given the safety-critical nature of automotive parts.

Advanced Technology and Manufacturing Excellence

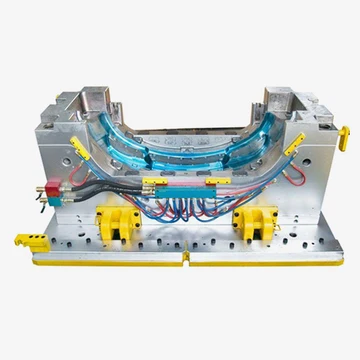

ISO certification often reflects a manufacturer’s commitment to adopting cutting-edge technologies and maintaining high standards of craftsmanship. Top-tier injection molding facilities invest heavily in the latest machinery, such as multi-cavity molds, hot-runner systems, and robotic automation, to ensure high efficiency and accuracy. These manufacturers utilize advanced simulation software for mold design, which minimizes trial-and-error, shortens development cycles, and enhances part quality. Automated inspection tools, including 3D scanning and coordinate measuring machines, facilitate rigorous quality control, enabling manufacturers to consistently produce parts with tight tolerances and superior surface finishes. Ongoing staff training, adherence to process protocols, and investments in innovation are hallmarks of an ISO-certified company, ensuring that clients receive parts that meet or exceed industry standards.

Diverse Material Compatibility and Custom Solutions

A reputable ISO-certified automotive injection molding manufacturer offers a broad palette of materials suitable for different applications, from impact-resistant bumpers to heat-resistant dashboards. They understand that the choice of material plays a vital role in part performance and longevity, especially under extreme environmental conditions. These manufacturers have extensive expertise in working with high-performance plastics, reinforced composites, and specialty formulations customized to meet specific automotive specifications. They work closely with clients to develop tailored solutions that balance strength, weight, aesthetics, and cost-effectiveness. Their experience in handling complex designs, multi-material inserts, and over-molding techniques allows automakers to innovate and bring distinctive features to market confidently, knowing their parts are produced to the highest quality standards.

The Value of Strategic Partnership and Support

Partnering with an ISO-certified manufacturer goes beyond just transactional relationships; it involves collaboration and strategic support throughout the product lifecycle. These companies often offer comprehensive services including design consultation, rapid prototyping, and molding process optimization. Their quality management systems facilitate transparent communication, traceability, and swift response to any production issues. Furthermore, their certifications demonstrate a commitment to continuous improvement, which benefits clients through enhanced efficiency, reduced costs, and improved product innovation. For automakers, working with a trusted, ISO-certified manufacturer means gaining a reliable partner capable of scaling production while maintaining strict quality control, ultimately helping to accelerate time-to-market and reduce overall costs.

Embracing Sustainability and Future Growth

An increasing focus on environmental responsibility is shaping the future of automotive manufacturing. ISO-certified injection molders are now incorporating sustainable practices and eco-friendly materials into their workflows. They implement energy-efficient machinery, waste reduction protocols, and recycling initiatives to minimize environmental impact. Many also explore development in bio-based plastics and virgin material recycling, aligning their operations with automotive industry sustainability goals. Adopting such practices not only benefits the planet but also adds value by meeting consumer demand for greener vehicles.