Unlocking the Secrets of Antenna Innovation: Discover What's Revolutionizing the Industry!

Antenna technology is at the heart of modern communication systems, playing a critical role in enabling connectivity across various sectors, including telecommunications, broadcasting, and even satellite communications. The importance of antennas cannot be overstated; they facilitate the transmission and reception of signals that allow us to communicate seamlessly. As the demand for faster and more efficient communication grows, so too does the need for innovation within the antenna manufacturing industry. Manufacturers are continuously pushing the boundaries of technology to meet these evolving needs, paving the way for groundbreaking advancements that impact our daily lives.

The Evolution of Antenna Technologies

The journey of antenna technology dates back to the early 20th century, with the invention of the dipole antenna, which laid the groundwork for future developments. Over the decades, antennas have evolved significantly, adapting to the burgeoning demands of communication systems. Key milestones include the introduction of Yagi-Uda antennas for television reception in the 1950s and the development of phased array antennas in the 1970s, enabling advanced radar and satellite communications. Personal anecdotes from friends in the engineering field often highlight how these innovations have transformed industries. For instance, a friend who works in aviation frequently discusses how modern antennas have drastically improved the reliability of in-flight communications. Today, we see antennas tailored for specific applications, utilizing advanced materials and designs that enhance their functionality and efficiency.

Key Innovations in Antenna Manufacturing

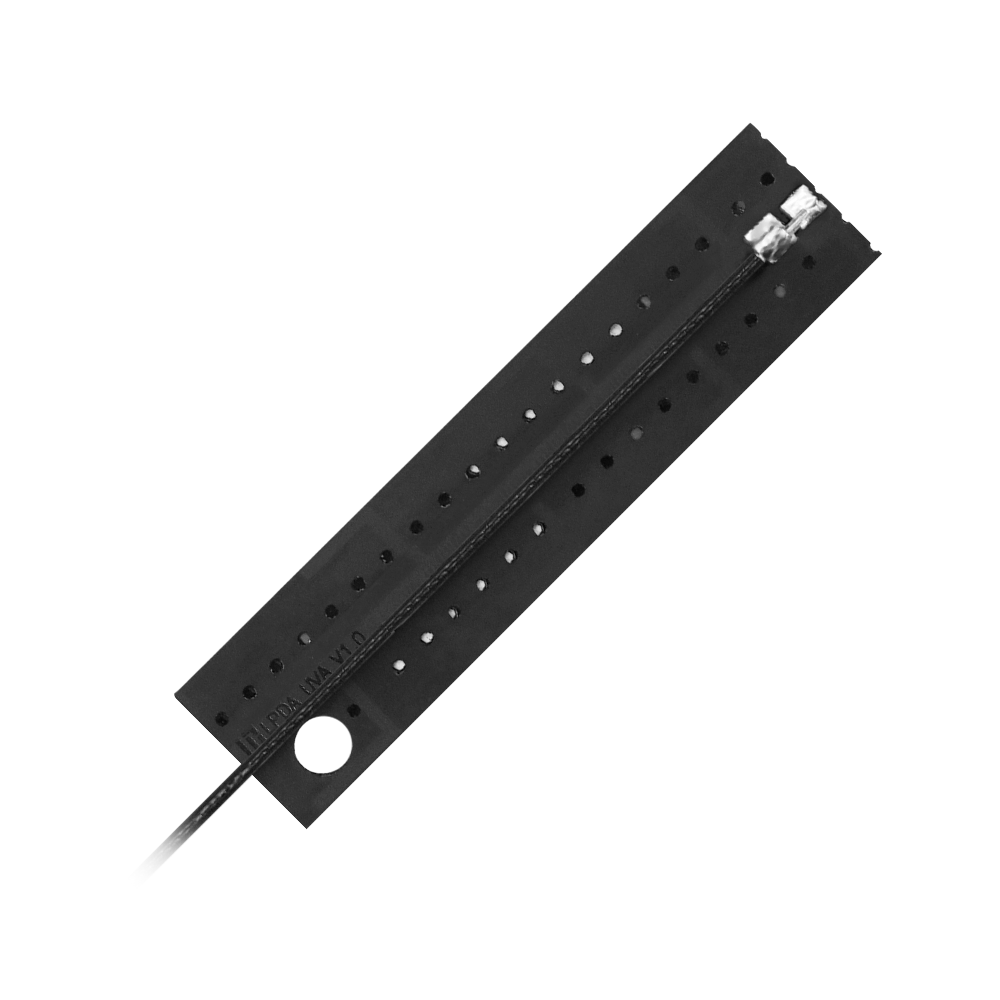

The manufacturing processes of antennas have witnessed remarkable innovations in recent years, significantly impacting performance metrics such as gain, bandwidth, and efficiency. One standout development is the use of advanced materials like metamaterials, which enable the creation of antennas with unique properties that were previously unattainable. Additionally, the adoption of 3D printing technology has revolutionized antenna design and production, allowing for rapid prototyping and customization at a fraction of traditional manufacturing costs. A colleague shared their experience working with 3D-printed antennas, noting how this technology enabled their team to iterate designs quickly, leading to faster project completion and improved performance. Furthermore, the integration of simulation software in the design phase has streamlined the manufacturing process, reducing errors and enhancing overall product quality.

Impact of Emerging Technologies on Antenna Design

Emerging technologies such as 5G, the Internet of Things (IoT), and millimeter-wave (mmWave) communications are reshaping the landscape of antenna design and manufacturing. The rollout of 5G networks requires antennas capable of operating at higher frequencies and supporting massive data throughput. This shift presents both challenges and opportunities for manufacturers, as they must develop antennas that are not only efficient but also compact enough to fit into smaller devices. A friend involved in IoT projects often discusses how the proliferation of connected devices necessitates antennas that can maintain performance while integrating seamlessly into various applications. The challenges of designing antennas for mmWave frequencies, characterized by shorter wavelengths and increased susceptibility to obstacles, push manufacturers to innovate continuously, thereby driving the industry forward.

Future Trends in Antenna Manufacturing

Looking ahead, several trends are poised to define the future of antenna manufacturing. Sustainability is becoming a crucial consideration, with manufacturers exploring eco-friendly materials and processes to reduce their carbon footprint. Miniaturization is another significant trend, driven by the demand for smaller, more efficient devices that can operate in increasingly crowded frequency spectrums. As technologies converge, we may also witness an integration of antennas with other components, such as sensors and communication chips, creating multifunctional devices. Personal experiences shared by friends in the tech industry emphasize the growing market demand for such integrated solutions, making them a focal point for manufacturers aiming to stay competitive. As the industry evolves, manufacturers must remain agile, adapting to these trends to meet the ever-changing needs of consumers and businesses alike.

Transformative Trends in Antenna Manufacturing

In summary, the antenna manufacturing industry is undergoing a transformative phase driven by innovation and technological advancements. From the historical evolution of antenna technologies to the latest manufacturing innovations and the impact of emerging technologies, it is clear that antennas play a pivotal role in facilitating communication in our interconnected world. As we look to the future, staying informed about these developments is essential for those interested in technology and telecommunications. The continuous pursuit of innovation in antenna manufacturing not only enhances performance but also shapes the future of connectivity, making it an exciting field to watch.