Unlocking the Secrets of Custom Antennas: Transform Your Connectivity Today!

In a world where connectivity is key, understanding the importance of custom designed antennas has never been more crucial. Unlike standard antennas that are designed for mass production, custom antennas are tailored specifically to meet unique requirements, enabling enhanced performance and versatility. These bespoke solutions can significantly improve signal quality, coverage, and overall reliability, making them indispensable in various technology-driven sectors. As we delve deeper into the realm of custom antennas, we will explore their applications across different industries, the intricate design process they undergo, and why opting for a custom solution could be the game changer you need for your connectivity challenges.

Understanding Custom Designed Antennas

Custom designed antennas are specialized devices crafted to meet specific communication requirements that generic, off-the-shelf antennas cannot fulfill. While standard antennas are mass-produced to suit a wide array of uses, custom antennas are engineered to achieve optimal performance for particular applications. Key components include the antenna type (such as dipole, monopole, or patch), frequency range, gain, and radiation pattern. What sets custom antennas apart is their ability to be tailored in terms of size, shape, and material to ensure they can operate efficiently within intended specifications. This unique nature allows for enhanced performance in various environments and applications, making them an essential component for many technological advancements.

Applications of Custom Antennas

The versatility of custom antennas means they find applications across numerous industries. In telecommunications, they play a pivotal role in enhancing mobile network signals, ensuring users can maintain seamless connectivity even in challenging environments. For instance, a friend of mine who works in telecommunications shared how custom antennas enabled their network to cover previously unreachable rural areas, effectively bridging the digital divide. In the realm of IoT devices, custom antennas are essential for ensuring reliable data transmission between devices, particularly in smart homes and industrial applications. Aerospace is another field where custom antennas are critical, as they must withstand extreme conditions while ensuring reliable communication for navigation and data transmission. Similarly, in the automotive industry, custom antennas are being used to support the growing demand for connected cars, helping to deliver real-time data to drivers and manufacturers alike.

The Design Process of Custom Antennas

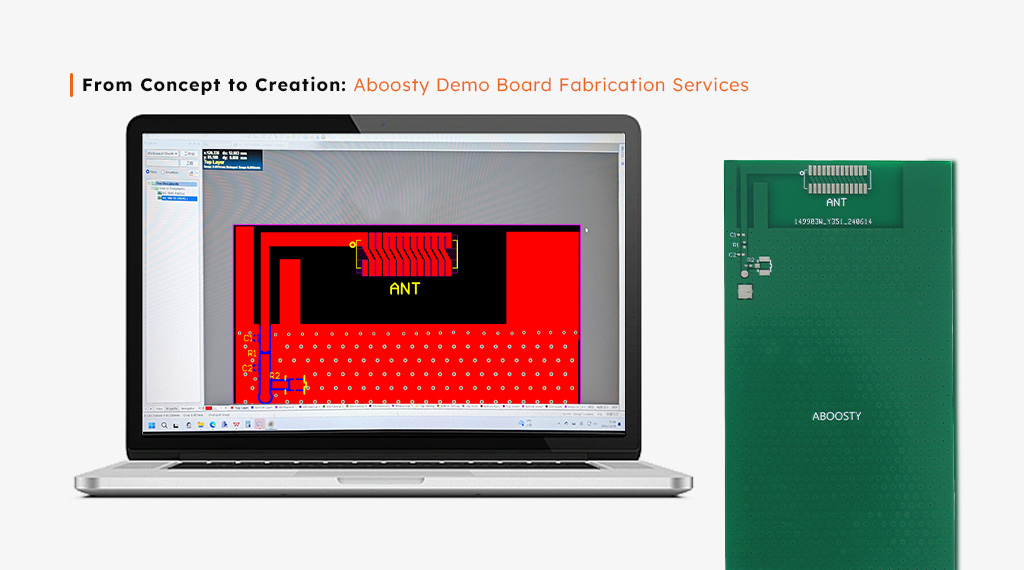

The design process of custom antennas is both intricate and methodical. It begins with gathering initial requirements, where engineers assess the specific needs of the project, including frequency, size, and environment. Following this, simulation tools come into play, allowing for virtual modeling of the antenna's performance in various scenarios. This stage is crucial, as it helps identify potential issues early in the design process. Once simulations are complete and adjustments made, prototyping begins. Engineers create physical models to test their designs, examining factors like signal strength and radiation patterns. Testing is a vital phase, as it ensures that the antenna performs as intended in real-world conditions. The materials used in the construction of custom antennas also play a significant role in their performance, with options ranging from metals for strength to composites for lightweight designs, tailored to the specific application.

Challenges in Designing Custom Antennas

Designing custom antennas is not without its challenges. Engineers often face size constraints, particularly in applications such as mobile devices where space is at a premium. Frequency limitations can also pose significant hurdles, as antennas must be designed to operate efficiently within specific bands. Environmental factors, such as weather conditions and physical obstructions, can further complicate the design process. To overcome these challenges, engineers often rely on advanced simulation techniques that allow for iterative testing and refinement of designs before final production. By addressing these issues proactively, the likelihood of achieving a successful custom antenna design increases significantly.

Significance of Custom Antennas in Modern Connectivity

Custom designed antennas are revolutionizing connectivity across various sectors by providing tailored solutions that enhance performance and reliability. From telecommunications to automotive applications, the significance of these bespoke devices cannot be overstated. By understanding the design process and the unique challenges involved, businesses and individuals can make informed decisions about integrating custom antennas into their projects. If you're looking to elevate your connectivity experience, considering a custom solution may be the key to unlocking new possibilities.