In the demanding world of mining and heavy industry, the reliability and efficiency of slurry pumps are vital for ensuring continuous operations and maximizing productivity. CNSME Pump has established itself as a dependable supplier known for manufacturing durable and high-performing slurry pumps tailored for some of the toughest industrial environments. With a focus on quality, technological innovation, and customer-centric solutions, CNSME has become a trusted partner for companies across the globe. Their reputation is built on delivering products that can withstand extreme conditions, operate with minimal maintenance, and provide long-term value in challenging applications.

Expertise in Heavy-Duty Design and Construction

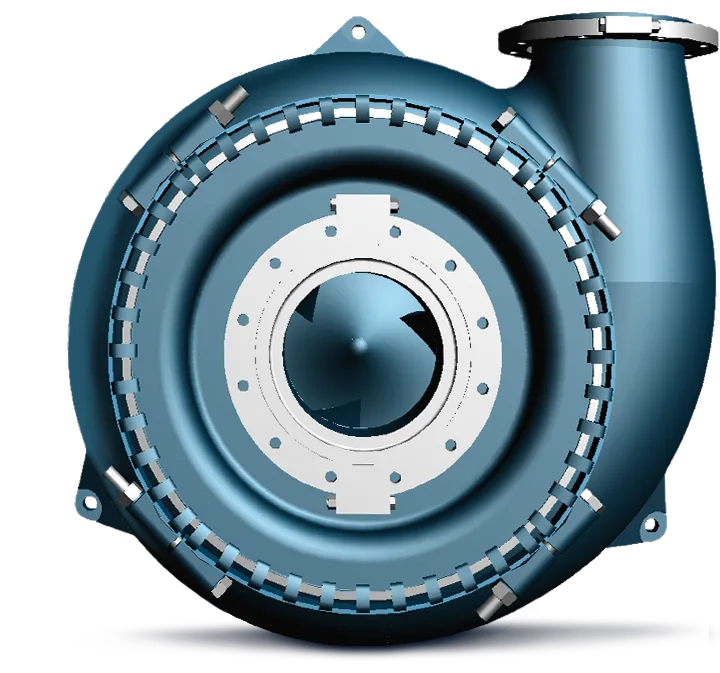

CNSME Pump’s strength slurry pump supplier in designing heavy-duty slurry pumps capable of handling abrasive, corrosive, and high-density slurries. Their engineers pay meticulous attention to designing components that endure the harshest work conditions, such as high impact and continuous wear. The structural integrity of each pump is reinforced through robust materials and innovative engineering techniques, ensuring they maintain performance even under the most strenuous loads. This focus on durability and strength means that mining companies and industrial operators do not need to worry about frequent breakdowns or costly repairs, as CNSME’s pumps are built to last and keep operations running smoothly with minimal downtime.

Commitment to Quality Materials and Manufacturing Precision

The quality of a slurry pump directly correlates to the materials used and the precision of manufacturing processes. CNSME invests significantly in sourcing premium materials such as high-chrome alloys, rubber-lined components, and corrosion-resistant composites. These materials are carefully selected for their ability to resist abrasion, corrosion, and impact, which are common challenges in mining and industrial environments. Coupled with advanced manufacturing processes like CNC machining, casting, and thorough quality inspections, CNSME ensures each pump component meets strict tolerances and quality standards. These practices guarantee that every pump leaving their facility maintains high reliability and performance, providing customers with peace of mind knowing that their investment is built on a foundation of quality.

Innovative Technology for Enhanced Efficiency

CNSME Pump’s dedication to technological advancement is a key factor in its reputation as a reliable supplier. They continually incorporate the latest innovations into their products, such as optimized impeller designs that improve flow dynamics and reduce energy consumption. Advanced simulation tools like CFD (computational fluid dynamics) are employed during the development phase to refine pump performance and minimize wear. As energy efficiency becomes a priority for many mining and industrial companies, CNSME’s pumps are designed to deliver high output levels with lower power requirements, translating into cost savings over the long term. This focus on efficiency not only reduces operating costs but also supports environmental sustainability by minimizing energy use.

Tailored Solutions for Diverse Industry Needs

Recognizing that every mining or industrial site has unique challenges, CNSME offers tailored solutions rather than one-size-fits-all products. Their team of experienced engineers collaborates with clients to understand specific operational conditions, fluid characteristics, and performance expectations. Based on this understanding, CNSME designs custom impeller configurations, sealing systems, and material compositions that best suit the application. Whether dealing with highly abrasive ore slurries, corrosive chemicals, or viscous materials, the company ensures that each pump is optimized for maximum efficiency, durability, and ease of maintenance. This customer-centric approach ensures operation continuity and minimizes costs associated with unexpected breakdowns or suboptimal performance.

Comprehensive Support and After-Sales Service

A key component of CNSME’s reputation as a reliable slurry pump supplier is its comprehensive support infrastructure. Beyond manufacturing, the company offers extensive after-sales services, including installation support, routine maintenance, troubleshooting, and spare parts supply. Their global network of service centers allows quick response times and accessible technical assistance wherever the customer is located. This proactive support helps industries minimize downtime and extend the lifespan of their pumps. CNSME's technical teams also provide training to plant personnel, enabling them to better understand, operate, and maintain the equipment—further emphasizing their commitment to complete customer satisfaction and operational reliability.

Future-Ready Solutions and Industry Leadership

CNSME remains committed to innovation and staying ahead in the industry by investing in future-ready technologies. They are exploring the integration of smart sensor systems into their pumps, which can provide real-time data on performance, wear, and operating conditions. These intelligent systems help companies perform predictive maintenance, avoid unexpected failures, and optimize energy consumption. CNSME also actively develops more environmentally friendly pumps that focus on energy efficiency and reduced environmental impact. Their ongoing RD efforts demonstrate a forward-looking strategy that aims to meet the evolving demands of mining and industry sectors, solidifying CNSME’s position as a leader in reliable slurry pumping solutions.